Welcome to Weihai Lubo Electronic Technology Co., Ltd. official website!

Welcome to Weihai Lubo Electronic Technology Co., Ltd. official website!

Current Location : Home > OA Copier Parts > Raw Materials > Stainless Steel Sleeve

Product Name: Nickel Tube (Ni Sleeve)/Nickel Copper Nickel Tube (Ni-Cu-Ni Sleeve)

[Product Advantage]

- Exclusive supply of raw materials IH heating

3 layer metal sleeve:

Copper layer in the middle (12 um) can increase the heat conductivity and improve the fixing effect.

The temperature difference between the left and right ends of the film can be improved by increasing the heat conductivity of left and right.

At the same time, because of the existence of copper layer, there is a considerable increase in life;

[ Product Purpose ]

- φ30 : Ricoh Ricoh 3502/3503 series film / Canon Canon 4035/4235 series film / Xerox Xerox 2270/275 series film substrate

- φ40 :Ricoh Ricoh 4501 series film, KM C754 series film substrate.

[ Product specifications ]

Material | ID(Φ) | T(um) | L(mm) | 1Box Package |

Ni Sleeve | 30mm | 40um | 230 ~ 400mm | 250ea |

40mm | 40um | 230 ~ 400mm | 160ea | |

50mm | 40um | 230 ~ 400mm | 60ea | |

55mm | 40um | 230 ~ 400mm | 60ea | |

60mm | 40um | 230 ~ 400mm | 60ea | |

Ni-Cu-Ni Sleeve | 30mm | 52um | 230 ~ 400mm | 250ea |

40mm | 52um | 230 ~ 400mm | 160ea |

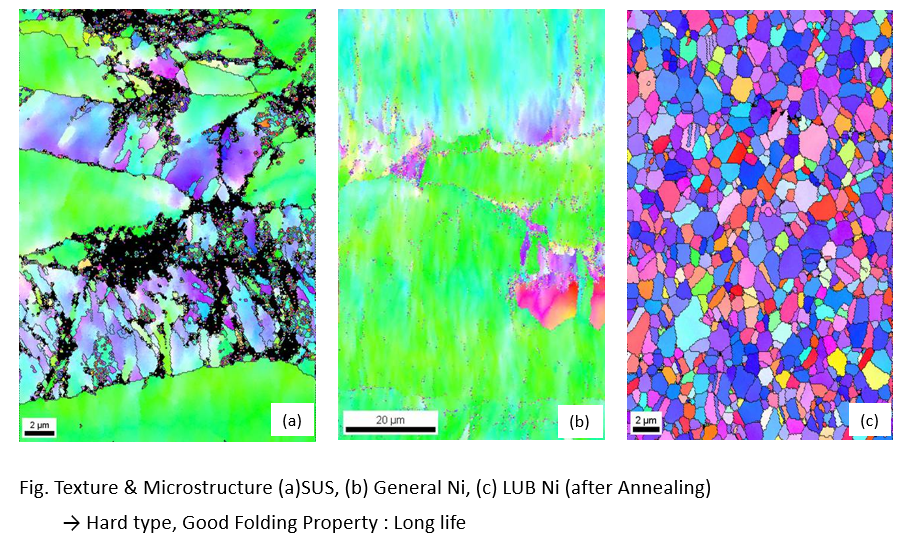

[ Product characteristics ]

Products | SUS Sleeve | General Ni Sleeve | LUB Ni Sleeve |

Manufacturing process | Deep drawing | Electroplating | Electroplating |

Characteristic | Normal | Normal | Ultra-High Strength |

Material | Stainless Steel | Nickel | Nickel + x alloy |

Hardness (HV) Before coating | 480~530 | 350~400 | 400~450 |

Hardness (HV) After coating | 300~400 | 200~300 | 450~550 |

MIT After coating (Folding tester) | 500~800 | 150~250 | 1400~2000 |

Tensile Strength (N/mm2) | 1300~1500 | 750~850 | 1400~1800 |

Elongation (%) | 1~2 | 5~6 | 2~3 |

Life Time (pages) | 50~150k | 50~100k | 150~200k |

Thermal conductivity (℃/sec) | 12 | 14 | 14 |

[ Product structure ]

[ Product packaging ]